EVO PT®

Podrobnosti k výrobku

-

Overview

- Optimised locating point

- Depth independent installation torque

- Support with complete CAE based designing

- Excellent process safety

- Standardisation potential

Branislav Gunda

The Evolution of self-tapping into plastic materials

The EVO PT® is the evolutionary development of self-tapping fasteners for thermoplastics. For the first time, this innovative fastening solution successfully integrates manufacturing and application knowledge with new methods based on physical computer simulations into the development process. The result of this cross-disciplinary approach is a screw with excellent connection properties.

Innovative forming thread

The innovative forming thread creates a torque curve during the installation phase, which is almost independent of the screw-in depth. Thus, a uniform tightening torque can be used in the production at different screw lengths.

The special lead-in feature creates a uniform load on the thread flanks when completely fastened, since the screw centres automatically in the pre-hole during the installation. Furthermore, this innovative thread allows an easy self-alignment in the pre-hole.

EJOT EVO CALC®

With the digital calculation service EJOT EVO CALC®, a prediction of the torques and preload forces according to component requirements is possible. Furthermore, in connection with the EVO PT® screw, we provide an individual FEM-supported component optimization. Thus, time and cost saving effects can already be realized in the design phase.

CAE services - component optimisation and individual design engineering assistance

We also support you during the development phase with our CAE services. With the help of innovative calculation and simulation tools we estimate the behaviour and the effect of our fastening elements on your component under various loads and then give you the respective recommendation. It is possible to calculate the clamp load relaxation of individual screw joints and also to analyse the behaviour of the complete assembly. More...

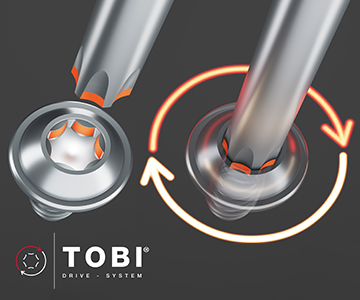

TOBI® Drive-System - The high-performance screw drive system

- Secure hold without magnetic bits or vacuum systems

- Axial alignment of screw and bit

- Longer bit life due to enlarged contact area (up to 70x higher)

- Reverse compatibility with standard internal hexalobular bits

- More information

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h01/h48/9356537462814/75Wx75H-.png)